Investigating Numerical Solutions Based on Effective Medium Theory for Solidification of PCM in Fins for HVAC

This research was conducted as a part of advanced independent study in department of mechanical engineering at UW-Madison, the objective of this study is to numerically investigate the thermal performance of metal fins and phase-change materials (PCM) for efficient heat removal in heat exchangers. The Numerical models are built in MATLAB and Python, and simulations are performed using ANSYS software. PCM is a heat storage unit with internal fins open to air at its top. The device receives heat through its horizontal base, on which aluminum vertical fins are fastened. Between the fins, phase-change material is kept.

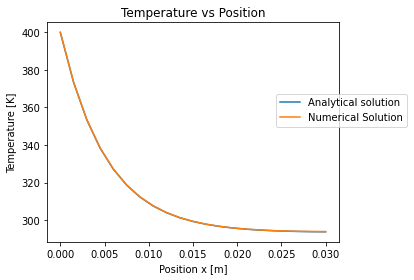

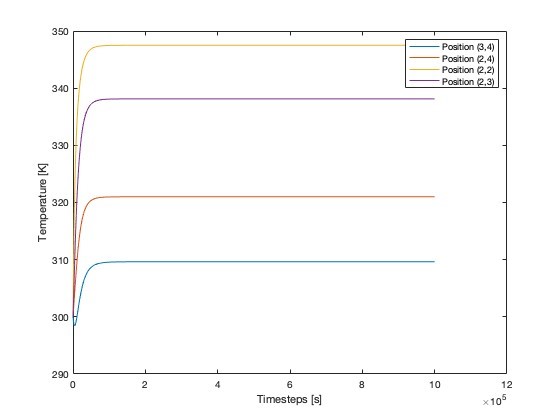

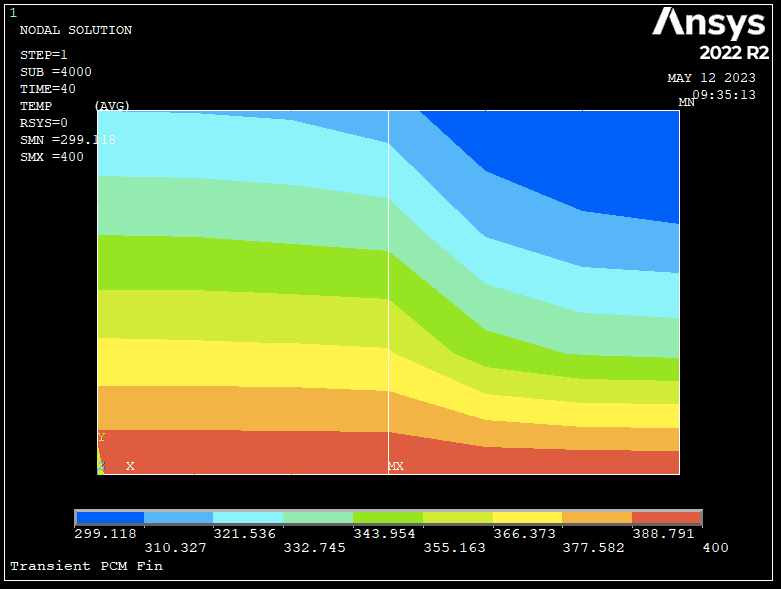

The problem is modeled as a transient analysis,and the computational domain consists of two sub-models: 1-D transient fin and 2-D transient PCM. FEA models transient 2-D and 1-D analyses of the PCM-fin and fin problems, respectively. The computational results demonstrate the dependence of the transient phase-change process, expressed in terms of the me and position of the PCM, on the thermal and geometrical parameters of the system, which are related to the temperature difference between the base and the mean melting temperature, as well as to the thickness and height of the fins. The analyzed numerical results are verified and fairly correspond to the verified benchmark results in the FEA tool.

To conclude this article, to compare the temperature distribution of the fin and PCM-fin in a heat sink with a constant-temperature vertical fin and the top exposed to air, numerical research is carried out using Euler's technique and FEA. MATLAB was used to perform transient one- and two-dimensional numerical analysis. In the simulations, a formulation that accounts for conduction inside the fins, conduction and convection in the PCM, and heat transmission to the surrounding air has also been tried in the FEA tool (ANSYS).

The computer findings have demonstrated how changes in the system's shape and boundary conditions impact the temperature distribution, and heat transport in a thorough parametric examination.

A transient one – and two - dimensional analysis has been used to try to generalize the findings. It has been observed that the specific heat plays an important role in the transient analysis. Phase change materials (PCMs) are substances that can absorb or release large amounts of heat energy while undergoing a change in their physical state, such as from a solid to a liquid or vice versa. The specific heat of a PCM is the quantity of heat energy needed to raise the temperature of the material by one unit (typically one degree Celsius or Kelvin) at constant pressure. The specific heat of a PCM is not constant throughout its entire operating temperature range and may vary significantly during phase change.

The results of the present study broaden the insight into the phenomena of the PCM temperature distribution in a vertical fin. The simulations can be utilized in the design of PCM-based cooling systems to show patterns and relationships that may be generalized.