My Publications

Computational Fluid Dynamics Simulation on Thermal Performance of Al/Al2O3/SWCNT Nanocoolants for Turning Operations

The objective of this study is to numerically investigate the thermal performance of cutting fluids dispersed with nanoparticles for effective heat removal during turning operations.

The simulations are performed using Ansys Fluent software, and the problem is modelled as a three-dimensional turbulent incompressible single-phase flow. The computational domain consists of a heated cutting tool and work piece, and nanocoolants are sprayed from a nozzle located above the machining zone.

Numerical Investigation on Thermal Performance of Duplex Nanocoolant Jets in Drilling of Ti-6Al-4V Alloy

The coolant used is a mineral oil into which different nanoparticles of Al2O3, TiO2, Cu, MWCNT, and SWCNT are dispersed by varying the volume concentration.

The variations in temperature, Nusselt number, and wall heat transfer coefficient, with respect to the volume fraction of nanoparticles and the Reynolds number, were investigated. It was concluded that Cu–Al2O3 nanoparticles dispersed in mineral oil depicted the most favourable heat transfer.

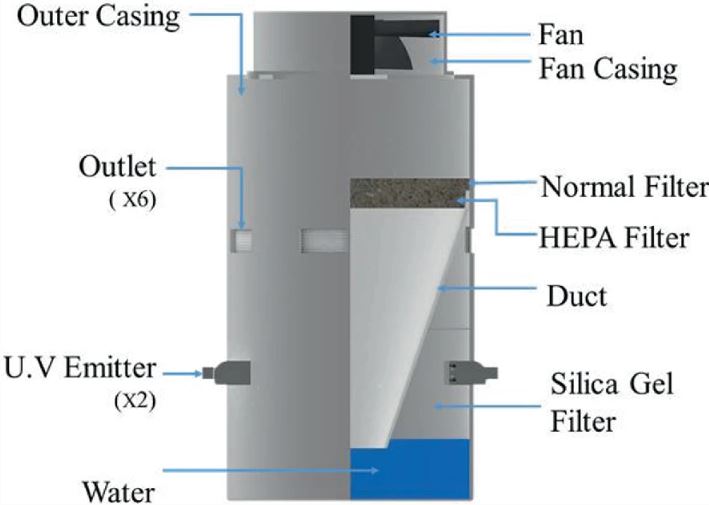

Centralized Smart Air Purifier System for Industrial Applications

The proposed centralized air purifier is able to eliminate air pollutants of 10 microns and above from the polluted air in the industrial environments and it operates on the concepts of connected devices. Thus an economical, smart and healthy air purifier is developed to suit industrial applications. The simulations are carried out in Ansys Fluent software to substantiate our model and empirical data.